A board for precise, reliable and specialized control

In the world of CNC systems and industrial automation, the internal components of drives play a very key role in the overall performance of the machine.

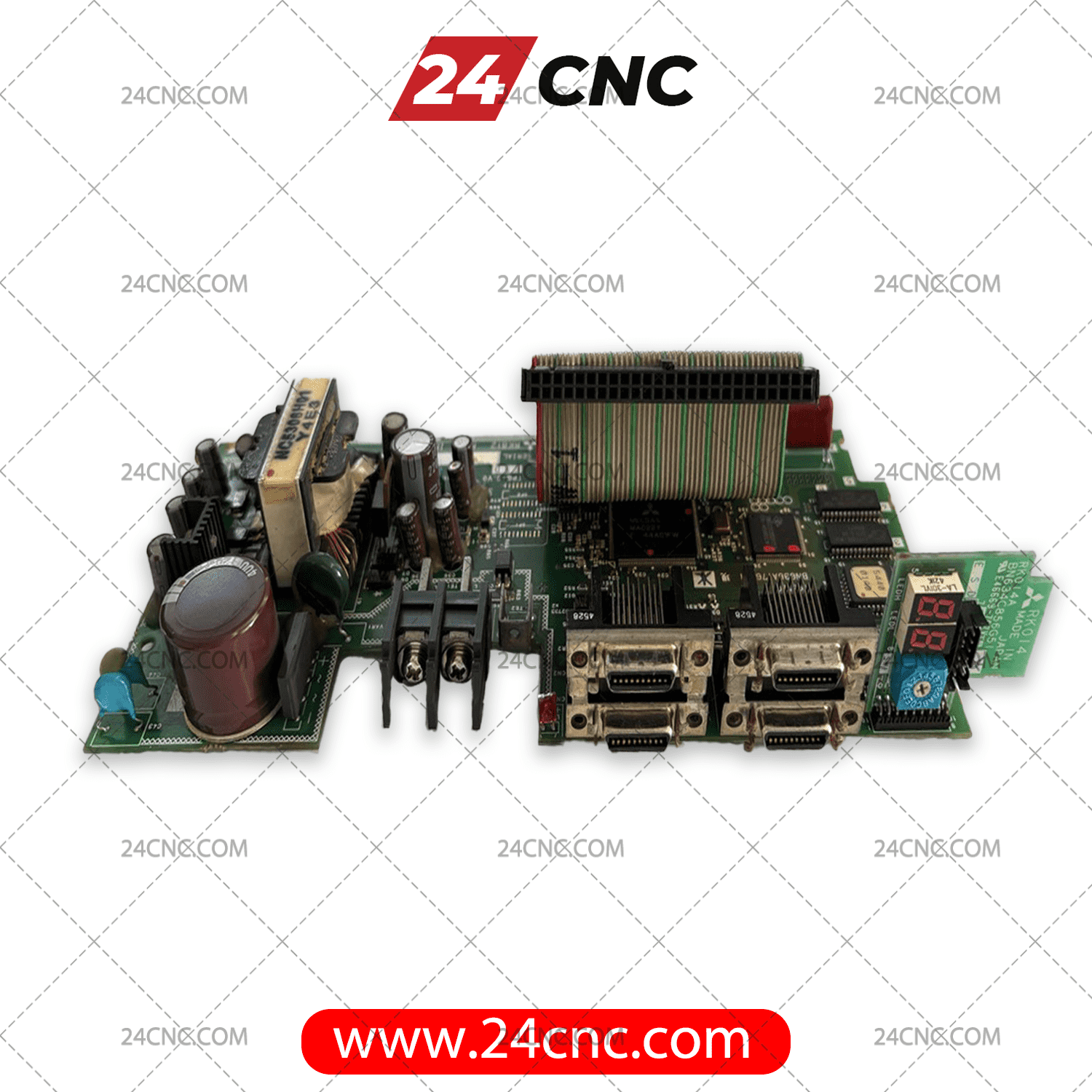

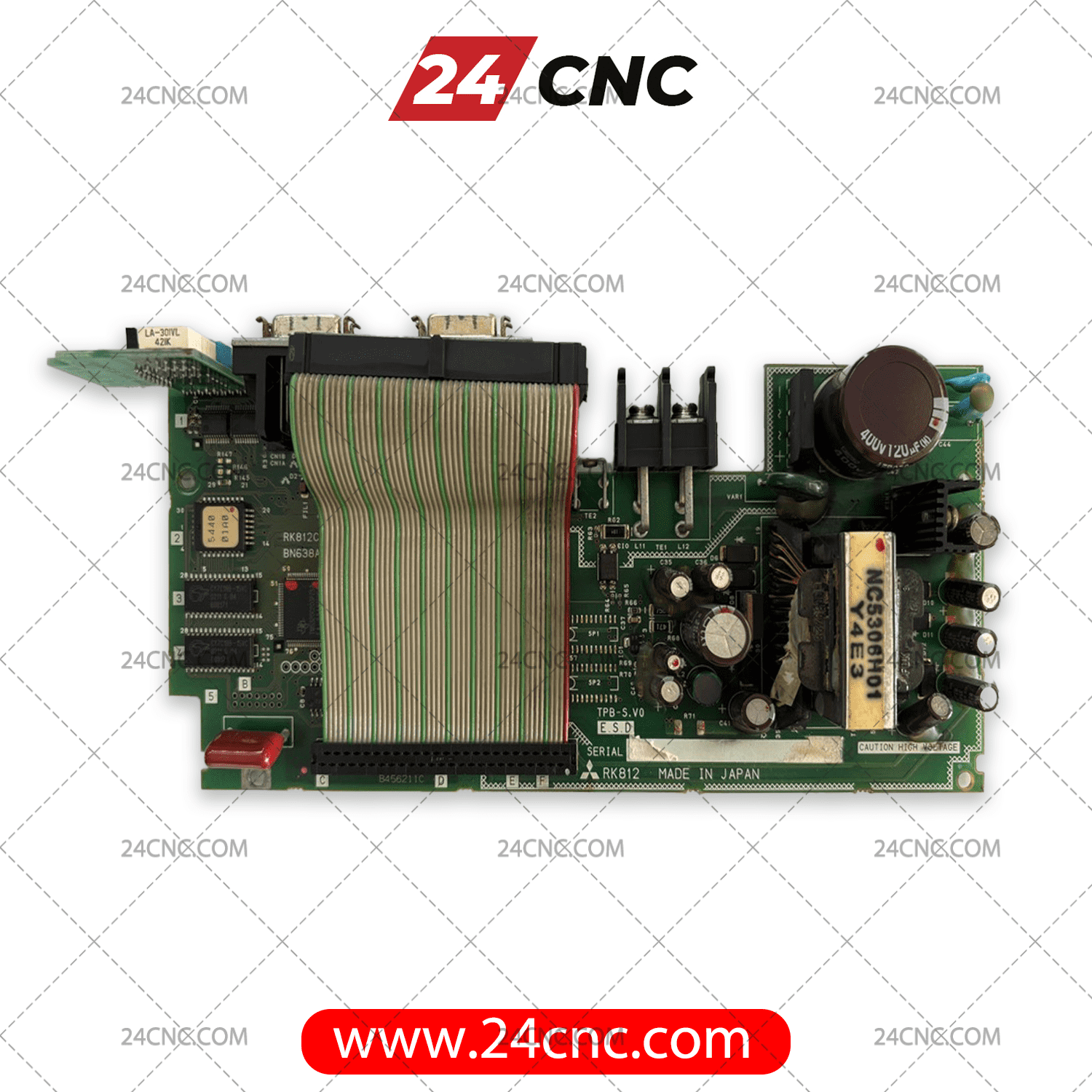

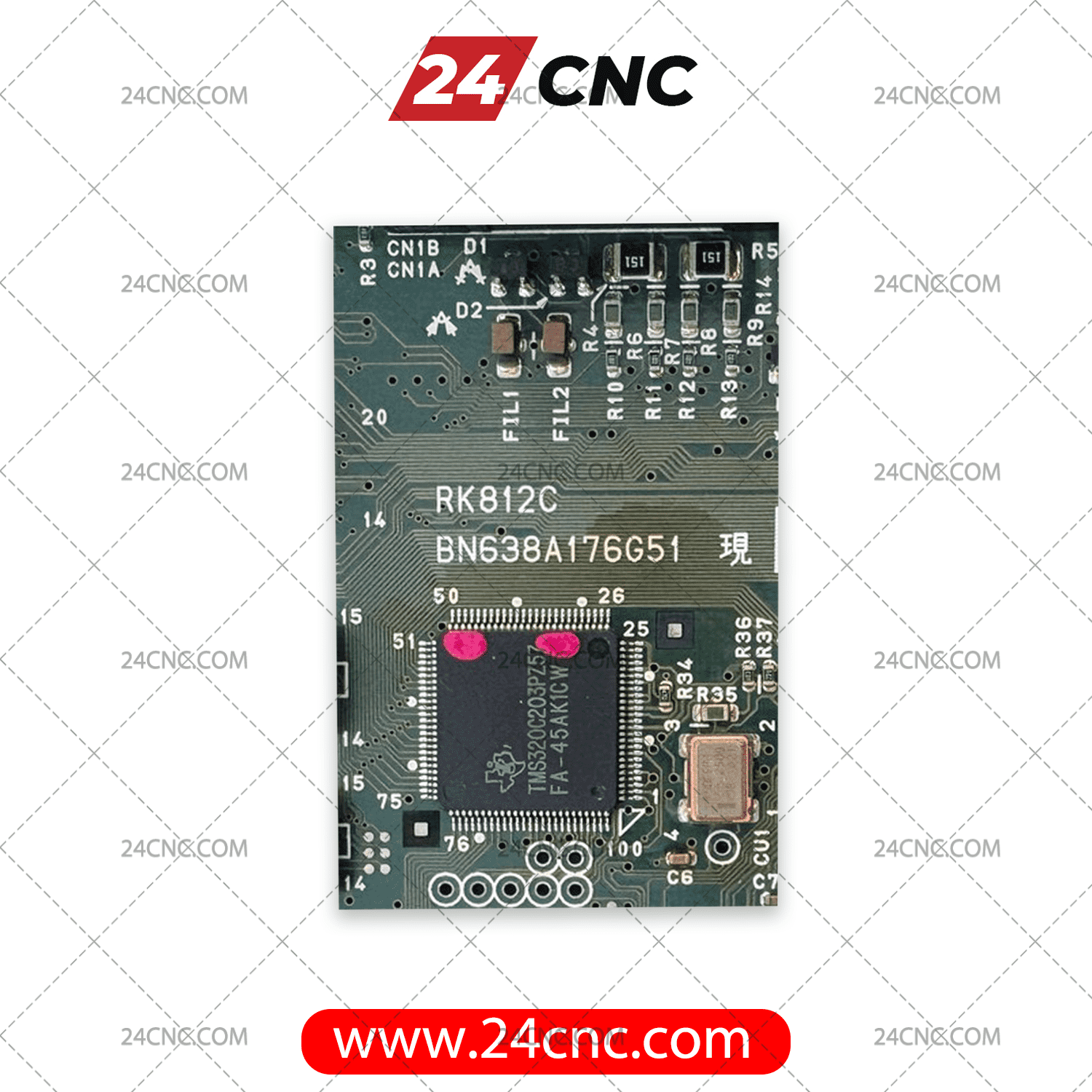

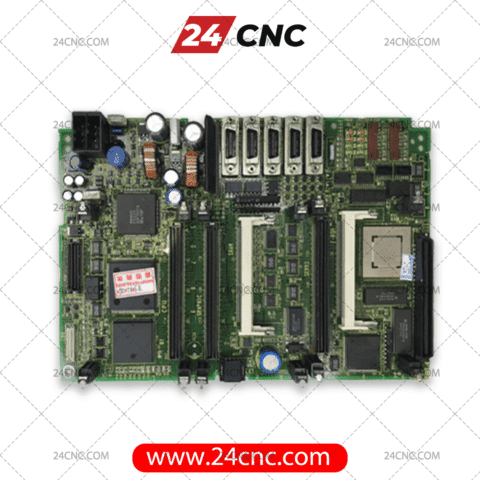

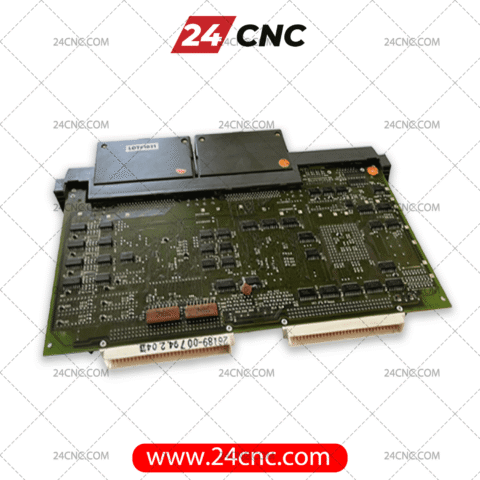

One of these components is the electronic boards, or PCBs. The Mitsubishi PCB board model RK812C BN638A176G51 is exactly one of those parts that is used for better spindle drive control with professional design, high performance and long-term durability.

This board, which is a product of the prestigious MITSUBISHI brand, supports specific spindle drives from this company and plays an important role in transmitting precise signals to control the speed and performance of the spindle.

Advanced technical structure, inside a seemingly simple board

At first glance, this board may look like a simple electronic component, but when we get into its details, we will realize that behind this design is a precise and intelligent architecture. The RK812C BN638A176G51 model is designed to be fully compatible with the MDS-B-SPJ2-75 and MDS-B-SPJ2-110 spindle drives.

This board plays a key role in processing the input and output signals of the spindle. Any errors or delays in this process can directly affect the final quality of the CNC machine’s performance.

Perfect coordination with specific spindle drive models

One of the points that makes this board valuable for use in various industries is its precise compatibility with two important models of Mitsubishi drives.

The MDS-B-SPJ2-75 and MDS-B-SPJ2-110 models, which are commonly used in advanced industrial machinery, require a precise control board that can operate at high speeds and under continuous working pressure, without errors and with complete stability. This perfect coordination between the board and the drive ensures that the system operates without the slightest disturbance.

A board from a reputable global brand

When the name Mitsubishi is heard in the industrial world, it is expected that quality, accuracy and durability are at the highest possible level. The RK812C BN638A176G51 PCB board is no exception to this rule. Mitsubishi is one of the old and well-known brands in the field of industrial control systems that has a long history of producing high-quality equipment.

Due to strict quality tests and optimized designs, the electronic boards of this brand perform reliably even in harsh industrial environments.

Uninterrupted performance in harsh industrial conditions

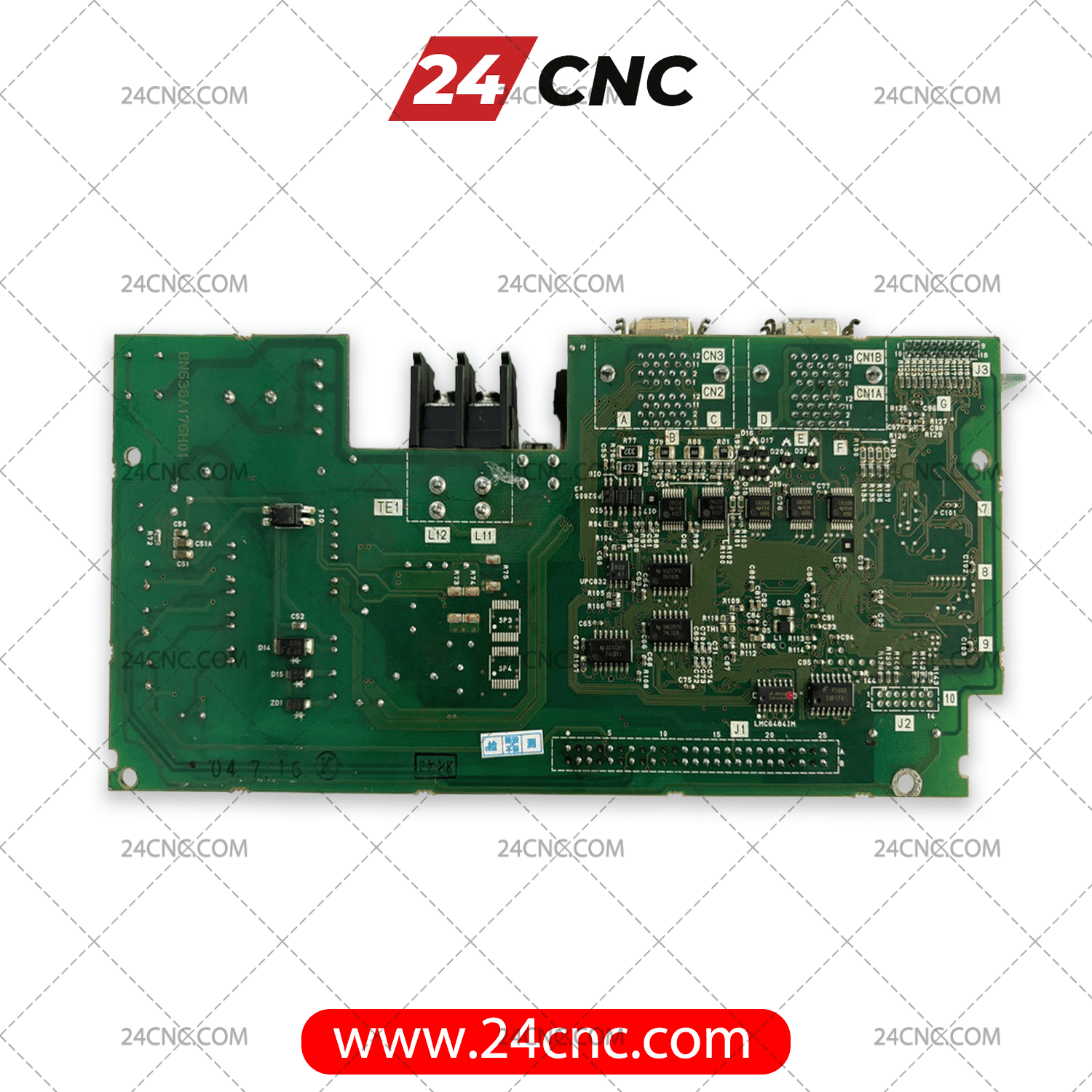

In industrial environments, we are always faced with electrical fluctuations, dust, humidity, and vibrations. However, the RK812C PCB board, using resistant materials and standard design, shows good resistance to these conditions.

This board can continue to work in high temperatures and harsh industrial environments without reducing efficiency. This means that you can safely count on this component as a stable part of your system.

Reduce device downtime with quick and easy replacement

One of the main advantages of this board is its quick and hassle-free installation. If there is a problem with the previous board, you can easily replace it with a new board without the need for complex settings or major changes to the device structure. This is especially useful for businesses where time is of the essence.

A long machine downtime can result in serious financial losses, but by using reliable and easy-to-install boards, this time can be minimized.

A key role in the accurate operation of the spindle

The main function of the board in these systems is to communicate the input commands from the CNC controller with the internal components of the spindle drive. If this communication is not accurate and instantaneous, we cannot expect accurate operation from the spindle. This is very crucial in machines such as CNC milling or turning machines, where accuracy of hundredths of a millimeter is important.

The RK812C board, with its precise processing structure, establishes this coordination well.

A small component with a big impact on the productivity of the machine

Electronic boards like the RK812C may not be very noticeable at first glance, but in fact, these components are what make the machine work with high precision and without interruption. When all commands, speed settings, protection signals and current control are transmitted through this board, its role becomes much more important than it seems.

It is this small board that can make the difference between an ordinary machine and a professional system, because in the world of industrial automation, it is the details that determine the final quality of the work.

Better control, more precision

No matter how high-quality the motor and drive are, if the control signals are disrupted, they cannot be expected to perform at their best. This is where the role of control boards such as the RK812C is most visible.

By precisely adjusting the currents and monitoring the drive status in real time, the board makes the spindle work exactly as the operator expects. No more, no less, just precise and stable.

There are no reviews yet.