Mitsubishi Servo Motor Model HA100NC-S; A Combination of Power, Precision, and Industrial Quality

In motion control and industrial automation systems, choosing a powerful and precise servo motor is a key factor in ensuring optimal device performance.

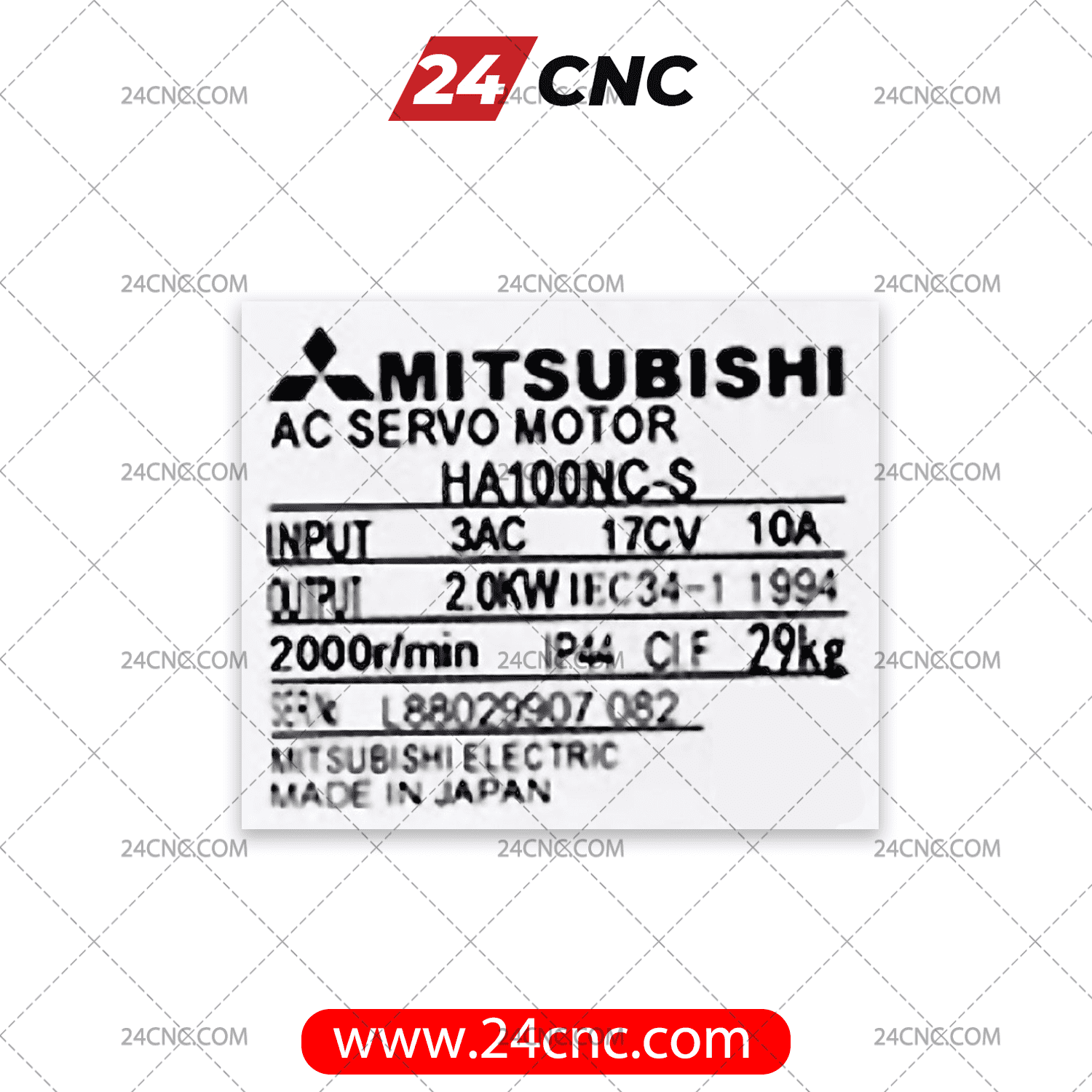

The MITSUBISHI servo motor model HA100NC-S with an output power of 2 kW and a torque of 42 Nm is one of the professional and industrial products of the renowned Mitsubishi Electric brand in Japan, designed for use in M500 series CNC systems.

This AC motor, which belongs to the HA series, offers stable and precise performance in heavy industrial applications by utilizing an engineered design and high-quality components.

The presence of a precise encoder, a design without electromagnetic brakes, and high mechanical resistance have made this product a reliable option in the machinery industry.

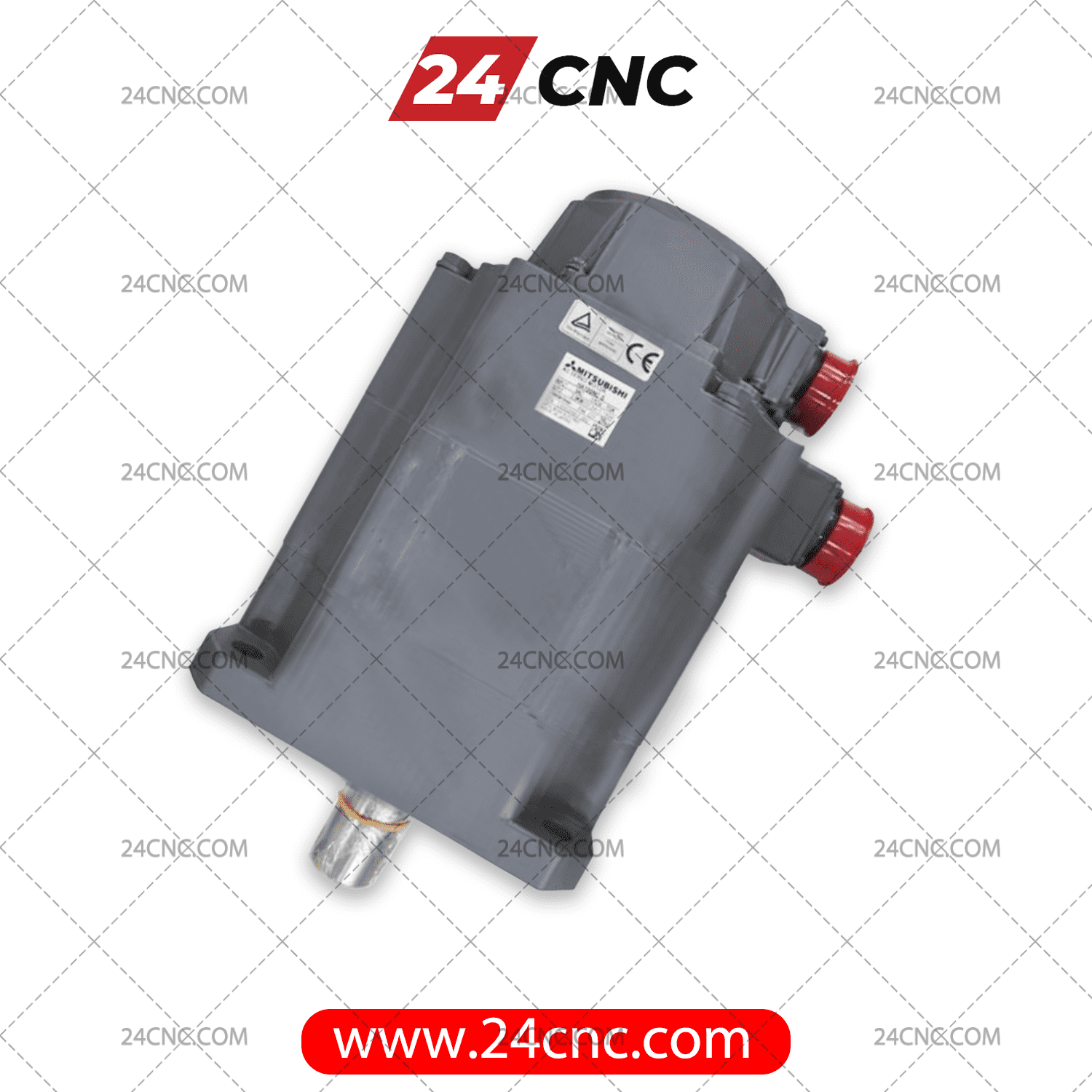

Industrial Design with Straight Shaft and Oil Seal

One of the most important features of the HA100NC-S model is the use of a straight shaft with an oil seal at the end of the shaft. This design reduces the penetration of contaminants and dust into the motor and increases its useful life. The lack of use of an electromagnetic brake also shows that this servomotor is designed for applications that do not require sudden stops and focus more on continuous and controlled movement.

In industries where accuracy and stability of performance are more important than quick stops, such features will play an important role in ensuring production quality and reducing depreciation.

High power with precise control

The output power of 2 kW along with the torque of 42 Nm has made this motor capable of moving relatively heavy loads with precise control. This amount of torque is sufficient and even more than required in many industrial applications such as heavy CNC machines, milling systems, lathes and automation equipment.

Also, despite the nominal speed of 2000 revolutions per minute (r/min), this servomotor is able to maintain accuracy at high speeds. In systems where maintaining stability in torque and speed is important, the performance of this motor is carried out without noticeable loss even under variable loads.

Three-phase input 170V with a current of 10 amps

The input voltage of this 3-phase motor is 170 volts AC. Its current consumption is also 10 amps, which, considering the power and torque provided, indicates high efficiency and acceptable efficiency in the operation of the motor.

The use of three-phase power in this model not only increases current stability and reduces performance fluctuations, but also helps extend the life of the motor. This feature is an important advantage in industrial environments where standard three-phase power is available.

OSE104 encoder for precise position control

This servomotor is equipped with an OSE104 encoder. Encoders are actually responsible for measuring and sending position and speed information to the control system. The presence of an encoder in this model allows for precise execution of motion commands and rapid position correction.

As a result, when used in CNC machines that require high motion accuracy, this servomotor will be able to comply with precise control standards. This encoder also allows for the implementation of closed-loop systems, which is critical for many professional applications.

Dimensional specifications and durable industrial body

The dimensions of the motor body are approximately 21.5 x 17.5 x 20 cm, and if the protective box is taken into account, it reaches 22 x 28.5 x 50 cm. These dimensions, along with the weight of 24 kg (with packaging), show that this servomotor is designed for use in heavy industrial systems.

The robust mechanical structure, high weight and balanced design allow for reliable and vibration-free installation. The shaft diameter is 3.5 cm and its length is 7.5 cm, which is perfectly suitable for transmitting high torque and can be connected to industrial couplings.

Without electromagnetic brake; suitable for continuous movement

This model of servomotor does not have an electromagnetic brake, which makes it suitable for continuous and controlled applications. In machines that do not require sudden stops or position holding and are mostly used in continuous production processes, the lack of a brake is not only not a hindrance but also reduces the complexity and maintenance costs of the system.

As a result, choosing this motor for systems such as milling, cutting and mechanical displacement that do not require quick stops will be a technical and economic choice.

Made in Japan, Guaranteed Quality

The Mitsubishi brand is one of the leaders in the automation and industrial electronics industry. This servo motor is also made under strict production standards in Japan and its manufacturing quality is guaranteed. In terms of durability, accuracy, reliability and compatibility with other automation equipment, Mitsubishi products are always at the top of the global market.

The use of original parts and a dedicated design for the M500 series ensure complete compatibility and efficiency in advanced control systems.

Installation Guide and Maintenance Tips

It is absolutely essential to observe safety and technical tips when installing this servo motor. The installation location must be properly ventilated and protected from shock, moisture and dust. Electrical connection must be made in accordance with Mitsubishi standards and with standard industrial cables. Regular maintenance includes checking the encoder condition, checking the cables, and lubricating the mechanical parts.

If used correctly and serviced periodically, this motor will provide stable and reliable performance for years.

Buy HA100NC-S Servo Motor from 24CNC Specialized Store

The 24CNC online store, relying on its specialized knowledge and experience in the field of CNC parts supply, offers the Mitsubishi servo motor model HA100NC-S in a completely original form with a guarantee of product authenticity, competitive prices and immediate delivery throughout the country.

The technical experts of this complex are also ready to provide expert advice on the compatibility of this motor with the desired control system before purchasing. If you need more information, a price inquiry or an installation guide, just contact the 24CNC complex via the website or by phone.

There are no reviews yet.